Laboratories depend on accurate data every single day. When results are even slightly off, decisions, research outcomes, and quality checks can suffer. One of the most trusted tools in analytical labs is the UV-VIS spectrophotometer. But like any precision instrument, it only performs well when it is properly cared for using a PM kit for UV-VIS spectrophotometer.

This is where a PM kit becomes important. Preventive care may not feel urgent until problems appear. By then, it is often too late. This guide explains why regular maintenance matters, how a PM kit supports reliability, and what labs gain by staying proactive rather than reactive.

Did you know ?

Regular preventive maintenance keeps UV-VIS spectrophotometers performing accurately by maintaining clean optics and reducing unexpected downtime? Source

What Happens When UV-VIS Instruments Are Not Maintained Properly?

Many labs focus heavily on calibration but overlook ongoing upkeep. Over time, small issues quietly affect readings without obvious warning signs.

Common problems caused by poor care include:

- Drift in absorbance values

- Reduced lamp efficiency

- Optical contamination

- Unexpected downtime during testing

- Increased repair costs

Even when the instrument is still powered on, the quality of data can decline slowly. These hidden inaccuracies can compromise compliance and research outcomes.

Why Does Preventive Maintenance Matter More Than Emergency Repairs?

Emergency repairs usually happen when testing has already stopped. At that point, pressure is high, and options are limited. Preventive care focuses on avoiding these situations entirely.

Regular UV-VIS spectrophotometer maintenance helps labs:

- Detect early signs of wear

- Keep optical paths clean and stable.

- Extend component lifespan

- Reduce unexpected breakdowns

- Maintain consistent data quality.

Preventive steps cost less than emergency repairs and protect long-term performance.

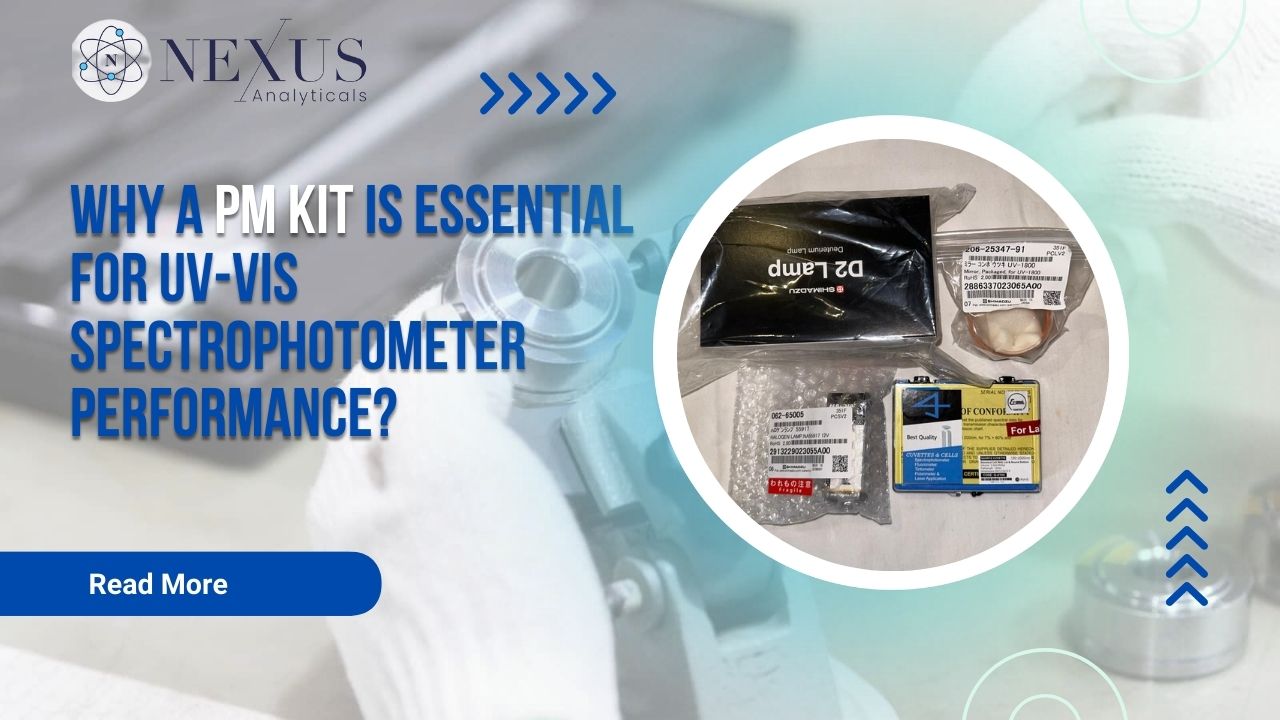

What Is a PM Kit and Why Is It Designed for UV-VIS Systems?

A preventive maintenance kit is not a random collection of parts. It is designed specifically to support routine servicing tasks that protect instrument accuracy.

A preventive maintenance kit is not a random collection of parts. It is designed specifically to support routine servicing tasks that protect instrument accuracy.

A PM kit for UV-VIS spectrophotometer typically supports:

- Optical cleanliness

- Mechanical stability

- Electrical reliability

- Safe replacement of wear components

Instead of guessing what needs attention, technicians follow a structured process that keeps performance stable.

How Does a Preventive Maintenance Kit Support Daily Lab Accuracy?

Accuracy is not only about calibration days. It depends on the instrument performing consistently between those checks.

A Preventive maintenance kit UV-VIS helps by:

- Reducing baseline noise

- Maintaining proper light intensity

- Ensuring smooth sample handling

- Preventing contamination buildup

These small improvements add up. They protect the reliability of everyday measurements that labs depend on.

Why Is Instrument Performance Directly Linked to Maintenance Quality?

Performance issues often begin quietly. Lamps age, optics collect residue, and alignment shifts slightly. None of this is visible unless someone looks closely.

Strong UV-VIS spectrophotometer performance depends on:

- Clean optical components

- Stable light output

- Reliable mechanical movement

- Controlled internal conditions

This is why many laboratories keep a dedicated PM KIT ready, ensuring routine checks can be completed without delay.

How Can a PM Kit Reduce Downtime and Service Costs?

Unplanned downtime disrupts workflows and deadlines. It also creates stress for staff and management.

Using a Spectrophotometer PM kit helps labs:

- Schedule maintenance at convenient times

- Avoid urgent service calls.

- Reduce costly part replacements.

- Maintain predictable budgets

When maintenance becomes routine, labs regain control over operations instead of reacting to failures.

What Role Do Trusted Suppliers Play in Maintenance Planning?

Access to the right tools and service support matters just as much as having the instrument itself. Reliable analytical instruments suppliers in India help labs source genuine maintenance kits, replacement parts, and technical guidance without long delays.

Working with trusted suppliers ensures that preventive maintenance remains consistent, compliant, and aligned with manufacturer standards.

What Are the Key Benefits Labs Notice After Regular PM Use?

Labs that adopt structured maintenance often report improvements beyond just instrument stability.

Common benefits include:

- More repeatable results

- Fewer failed validations

- Increased confidence in data

- Longer instrument lifespan

- Better audit readiness

These benefits impact not just equipment but overall lab credibility.

Questionnaire: Are You Maintaining Your UV-VIS System Effectively?

Ask yourself the following:

- Has the instrument shown drift between calibrations?

- Are lamp changes happening more often than expected?

- Do results vary between operators?

- Has unexpected downtime increased recently?

- Is maintenance mostly reactive instead of planned?

If you answered “yes” to any of these, a structured PM approach may be missing.

How Often Should Preventive Maintenance Be Performed?

Maintenance frequency depends on usage intensity, environment, and application type.

General guidance includes:

- Light usage labs: annual PM

- Moderate usage labs: every 6 to 9 months

- High-throughput labs: quarterly reviews

Following a consistent schedule helps prevent performance surprises.

What Should Labs Look for When Choosing a PM Kit?

Not all kits provide the same value. Labs should focus on quality, compatibility, and clarity.

Important considerations include:

- Instrument-specific design

- Clear servicing procedures

- High-quality replacement components

- Compatibility with manufacturer guidelines

Choosing the right kit makes maintenance simpler and more effective.

Actionable Steps to Protect UV-VIS Accuracy Starting Today

Instead of waiting for issues to appear, labs can take control now.

Practical actions include:

- Review current maintenance logs

- Identify missed preventive tasks.

- Schedule regular PM sessions.

- Train staff on basic upkeep

- Use structured maintenance tools.

Small steps taken consistently protect long-term accuracy and reliability.

Key Takeaway:

- Regular preventive maintenance protects the accuracy of UV-VIS spectrophotometer results.

- Small performance issues can grow into major failures without routine maintenance checks.

- A structured PM kit helps maintain stable optics, light output, and system reliability.

- Preventive maintenance reduces unexpected downtime and costly emergency repairs.

- Consistent upkeep improves data confidence, audit readiness, and instrument lifespan.

Frequently Asked Questions

Q1. What is the main purpose of a UV-VIS PM kit?

It helps maintain accuracy, reduce wear, and prevent unexpected instrument failures.

Q2. Can preventive maintenance replace calibration?

No. Maintenance supports performance, while calibration verifies measurement accuracy.

Q3. Does regular PM improve result consistency?

Yes. Clean optics and stable components reduce variability in measurements.

Q4. Is preventive maintenance only for older instruments?

No. New instruments also benefit from early preventive care.

Q5. Who should perform preventive maintenance tasks?

Trained technicians or qualified service professionals should handle PM procedures.